What happens when you “hire” your childhood friend to build something in your backyard with nothing but a sketch and a dream?

This is the story of how my friend Edegar spent four months turning a truck with 600 bamboo strips into an incredible web structure that became the talk of our neighborhood.

Edegar Miranda has been my friend since we were kids. When he moved to Recife 10 years ago, I stayed amazed by his bamboo work from afar. So when he mentioned visiting his mother in southern Brazil, I had an idea: “Why don’t you build something while you’re here?”

That conversation was two years ago. Here’s what happened when he actually showed up, ready to work.

The numbers: Nearly 600 bamboo strips, each 9 meters long. About 280 formed the main arches, the rest became an intricate web that defies physics and delights everyone who walks through it.

Why Bamboo? The Sustainable Building Material

Before diving into our construction story, let’s talk about why bamboo is such an incredible building material:

- Rapid Growth: Bamboo can grow up to 3 feet in 24 hours and reaches full maturity in 3-5 years (compared to 25-50 years for hardwood trees) - scientifically documented

- Strength: Tensile strength comparable to steel (40,000 psi for quality species) - verified by multiple engineering studies

- Flexibility: Natural flexibility makes bamboo structures earthquake-resistant and able to bend without breaking

- Carbon Sequestration: Bamboo absorbs 35% more CO2 than equivalent hardwood trees during growth

- Renewability: Harvesting doesn’t kill the plant - it regrows from its root system. Properly treated structures can last for decades.

The majestic Asper bamboo from our neighbor’s yard that provided much of our raw material.

What Could Go Wrong?

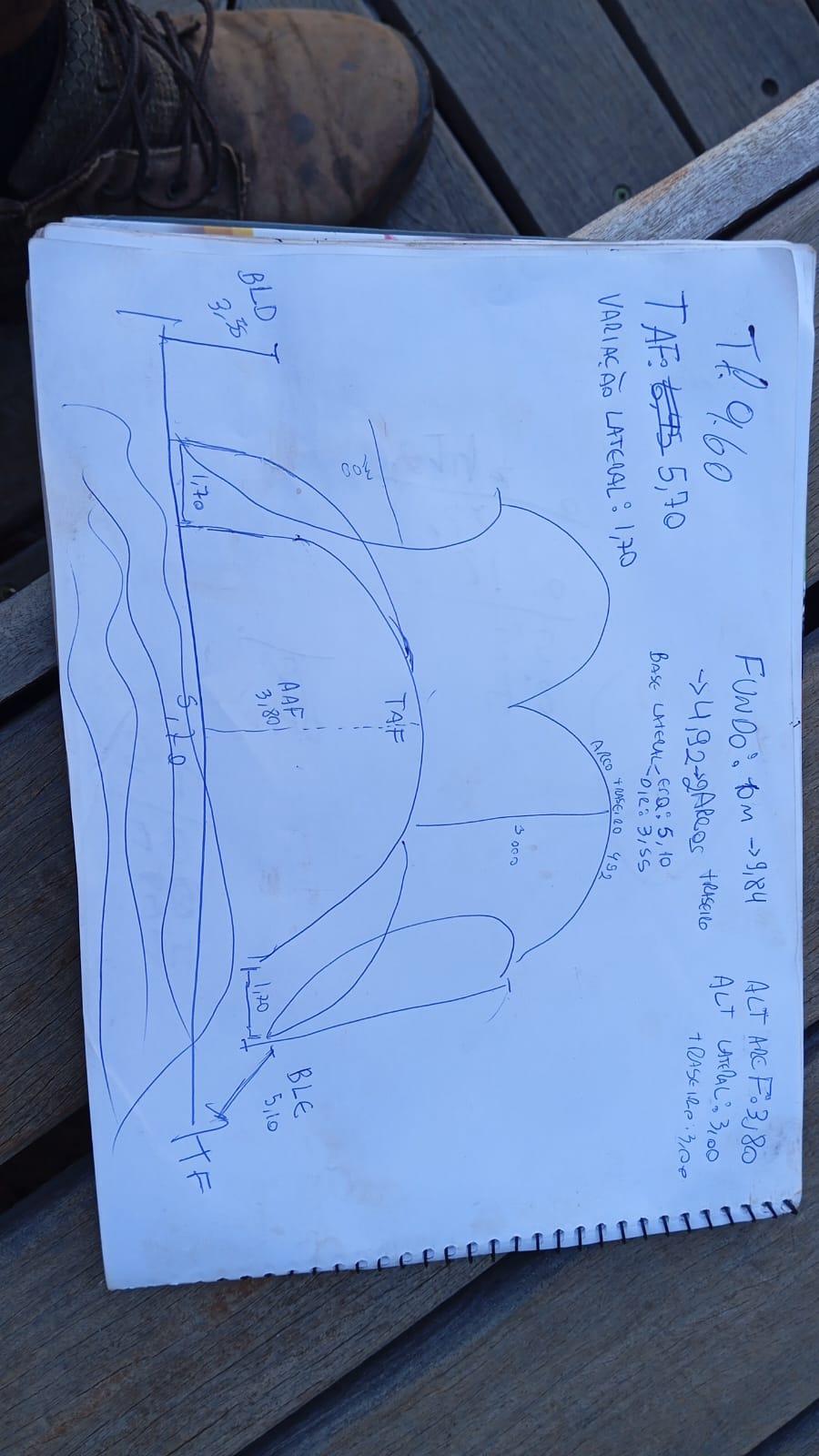

Here’s where it gets interesting: I essentially “hired” Edegar for this project without having any construction team, detailed plans, or even the right tools. I bought everything as we started planning but here is what we had as a initial sketch and our shared vision.

This humble sketch was our entire “blueprint” for the first two months. Yes, really.

For the first two months, we worked exclusively on creating the main arches using just basic tools. We didn’t even have a machete—which, as it turns out, is absolutely essential for bamboo construction.

Picture this: trying to split bamboo with whatever random tools we could find, making everything exponentially harder than it needed to be. But sometimes the best projects start with a little chaos.

Ripagem: The Art of Bamboo Strip-Making

One of the key techniques Edegar mastered was “ripagem”—the process of splitting bamboo into perfectly uniform strips for arches and structural work.

Hundreds of bamboo strips (called “ripas”) ready for assembly—each one split by hand with precision.

Here’s the reality check: I had to buy 600 pre-made strips from another state. The bamboo cost was reasonable, but transport? That was a third of our total budget with the strips.

We tried processing some of our neighbor’s bamboo ourselves, but quickly learned that proper strip preparation is both an art and a science. Without the right equipment and experience, we’d have spent months just on prep work. Sometimes buying quality materials is the smarter choice.

When Size Matters: Working with Massive Bamboo Canes

Handling and processing these massive bamboo canes required careful technique and a healthy dose of respect.

We were incredibly lucky to have our neighbor’s mature bamboo available for harvesting. Having Edegar—a true bamboo master—handle the first major cutting made all the difference.

These large canes served double duty: they became our work shelter (essential for those long construction days) and key structural elements in the final design.

Think of it this way: the thick, mature poles are like the skeleton of the structure, while the strips create all the intricate detail work. Both are essential, but they require completely different handling techniques.

The Machete That Changed Everything

The machete became a important tool—here it rests on the nearly completed structure.

Our essential machete photographed with the finished first arc placed in the background.

Month two brought our game-changer: a proper machete. The transformation was immediate and dramatic.

What suddenly became possible:

- Precise cuts in seconds instead of minutes

- Clean splits for perfect strips

- Accurate planning (faster work = better timeline estimates)

- Confidence that we could actually finish this ambitious project

Here’s the thing about bamboo construction: without the right tools, it’s not just harder—it’s nearly impossible. That machete wasn’t just a tool; it was the difference between a frustrating hobby project and a successful build.

Arch Assembly Process and Structural Engineering

The arches were assembled using modular techniques, allowing for flexibility and on-site adjustments. Each arch was constructed from multiple ripas (strips), bent and fixed into place.

Structural Resistance and Engineering Principles

What makes bamboo arches so incredibly strong:

- Hollow Structure: Like a steel tube, bamboo’s hollow interior provides maximum strength with minimal weight

- Fiber Arrangement: Bamboo fibers run longitudinally, creating exceptional tensile strength along the length

- Natural Taper: The natural taper distributes loads efficiently from base to tip

- Flexibility Factor: Unlike rigid materials, bamboo can flex up to 40 degrees without breaking

Our arches can easily support the weight of several people and resist strong winds because of these natural engineering properties. The web structure distributes loads across multiple points, making the entire pavilion incredibly stable.

Lesson learned: Modular assembly speeds up construction and allows for adjustments on site.

Finishing and Weatherproofing

After assembly, the bamboo was sanded, treated, and finished with a protective varnish to ensure durability and weather resistance. This step was critical for longevity.

Tip: Apply multiple coats of varnish and inspect for missed spots, especially at joints and ends.

Joints and Fastening

Joints were made using a combination of screws, guide holes, and sometimes a nailer. Special attention was given to the angles and overlaps to maximize strength.

Lesson learned: Pre-drilling guide holes reduces bamboo splitting and speeds up assembly.

Later, the process also involves “tabiques” which are big bamboo nails crossing multiple strips in diagonal.

When the Neighborhood Joined In

What started as a two-person project quietly became something bigger. Word spread, and soon neighbors were stopping by—some to help, others just to watch this crazy bamboo structure take shape.

Many evenings turned into impromptu work parties under the lights, with some friends jumping in to help complete sections.

Edegar’s dedication meant working well into the night to meet our timeline—true craftsmanship doesn’t watch the clock.

There’s something magnetic about construction projects. People are drawn to watch something being built, and before you know it, they’re asking “Can I help with that?” Community happens naturally around shared creation.

The Final Push and Completion

Working with bamboo like this takes time. Each piece needs to be shaped and positioned carefully. The whole structure depends on getting the connections right between hundreds of individual strips.

Time-lapse of the final day’s intensive work to complete the structure.

What struck me about this project was how Edegar stuck with it. For four months, he worked steadily and patiently. Two years ago we talked about doing this, and he actually followed through.

The final selfie after completing the bamboo web structure - tired but incredibly satisfied with the achievement.

Walking Through the Structure

Here’s a first-person walkthrough of the completed bamboo pavilion, recorded with Ray-Ban smart glasses. You can see how the intricate web structure creates interesting patterns of light and shadow throughout the space.

Now we have a covered outdoor space. During the day, the bamboo creates interesting shadow patterns. We added some lights for evening use.

People from the neighborhood stopped by to help or just watch the progress. It turned into more of a community thing than I expected.

Why Your Next Project Should Be Bamboo

After four months of watching this transformation happen in my backyard, I’m convinced: bamboo isn’t just an alternative building material—it’s often the better choice.

Here’s why bamboo wins:

- Environmental superhero: Every structure is a carbon sink that keeps growing after harvest

- Budget-friendly: Minimal processing compared to traditional lumber

- Universally available: Grows in most climates worldwide

- Incredibly versatile: From garden trellises to full pavilions and houses

- Community magnet: These projects naturally bring people together

Your Bamboo Building Survival Guide:

- Get the right tools first—especially that machete (trust me on this)

- Plan for patience—bamboo construction is methodical, not rushed

- Say yes to help—these projects turn into community events whether you plan it or not

- Respect the material—bamboo will teach you precision and humility

- Build modular—design in sections that can be adjusted as you learn

Ready to build something amazing? This pavilion will outlast most conventional structures while starting conversations about sustainable building every time someone walks through it.

The question isn’t whether bamboo can work for your project—it’s whether you’re ready to try something extraordinary.

Special thanks to Edegar Miranda for his dedication, the local community for their support, and my neighbor for sharing the Asper bamboo that became such an integral part of this project.

The Science Behind the Magic

Curious about the technical details that make this bamboo pavilion so strong? Here’s the engineering breakdown of what we built and why it works so well.

Mosso Bamboo (Phyllostachys edulis): The Strip Star

Remember those 600 strips I had to buy from another state? They’re made from Mosso bamboo (also called Moso or Giant bamboo). This species was chosen for very specific technical reasons:

Physical Characteristics:

- Diameter: Can reach 20cm (8 inches) in mature culms

- Height: Grows up to 28 meters (90 feet) tall

- Wall thickness: 8-15mm, providing excellent strength-to-weight ratio

- Our strips specifications: 9 meters long, width varying from 5cm to 9cm

Why Mosso for Construction:

- High tensile strength: 40,000 psi (comparable to steel) - verified by multiple studies

- Low shrinkage: Minimal dimensional changes when properly dried

- Excellent splitting properties: Creates clean, straight strips for construction applications

- Durability: With proper treatment, can last 15+ years in outdoor applications

- Growth cycle: Reaches full strength in just 3-5 years - scientifically confirmed

Treatment Process: Mosso bamboo requires proper curing and treatment to prevent insect damage and ensure longevity. The strips we purchased were professionally treated with boron-based preservatives, following established preservation standards.

Asper Bamboo (Dendrocalamus asper): The Structural Giant

Remember our neighbor’s massive bamboo that provided the large canes? That’s Asper bamboo (also called Betung bamboo), a giant tropical species that’s perfect for heavy construction:

Physical Characteristics:

- Diameter: 8-20cm (3-8 inches) at base, tapering toward top

- Height: Can reach 35 meters (115 feet)

- Wall thickness: 10-20mm in mature culms

- Internode length: 40-45cm, providing long sections for construction

Structural Properties:

- Compressive strength: 52 MPa (7,500 psi) - scientifically verified as highest among bamboo species

- Flexural strength: 87 MPa (12,600 psi) - confirmed by engineering studies

- Natural taper: Excellent for arch construction as loads decrease toward tips

- Quick growth: Reaches harvestable size in 3-4 years - confirmed by NCBI research

Why Asper for Framework:

- Heavy-duty applications: Research confirms Asper has the highest density and compressive strength among bamboo species

- Natural engineering: The hollow structure and fiber arrangement optimize strength-to-weight ratio

- Workability: Relatively easy to cut and shape with proper tools despite high density

- Local availability: Grows well in tropical and subtropical climates including Brazil

Construction Benefits: The combination of Mosso strips and Asper canes created an optimal building system - the Asper provided the robust framework while the Mosso strips allowed for intricate web patterns and detailed work.

How the Pressure Distribution System Works

The bamboo pavilion functions as an integrated structural system where loads are distributed through multiple pathways:

Primary Load Path - The Arches

The main Asper bamboo arches form the primary structural skeleton. Each arch works in compression along its curved length, transferring loads from the apex down to the foundation points. The natural taper of Asper bamboo is perfectly suited for this - the thickest sections at the base handle maximum compression forces, while the lighter tips carry minimal loads.

Secondary Load Distribution - The Web Network

The Mosso bamboo strips create a complex web that serves multiple structural functions:

- Load Sharing: When a point load is applied (like someone leaning on the structure), the web distributes that force across multiple strips and ultimately to several arches

- Lateral Stability: The web prevents individual arches from buckling sideways by providing continuous lateral bracing

- Redundancy: If one strip fails, loads automatically redistribute through alternate paths in the web

Tension vs. Compression System

The structure uses bamboo’s natural properties optimally:

- Arches in Compression: Bamboo’s excellent compressive strength (52 MPa) handles the primary downward loads

- Web in Tension: The interconnected strips work primarily in tension, utilizing bamboo’s exceptional tensile strength (40,000 psi)

- Combined Effect: This creates a self-stabilizing system where compression and tension forces balance each other

Why This Design is So Effective

- Multiple Load Paths: No single failure point can compromise the entire structure

- Natural Flexibility: The system can flex with wind loads and thermal expansion

- Progressive Loading: Forces gradually increase from the light web to the robust main arches

- Geometric Stability: The curved arches convert vertical loads into predictable compression forces

This pressure distribution system is why our pavilion can safely support multiple people while remaining lightweight and flexible. The bamboo’s natural engineering properties, combined with the web geometry, create a structure that’s both strong and resilient.

Links

If you want to hire Edegar, feel free to reach out him via Instagram: @edegar.miranda.7.

I also bought the bamboo strips ready for the building with the proper treatment from @xamabambu. Thanks Eder for the commitment and great material!